Kyocera TK-1160, ECOSYS P 2040 toner cartridge - how to do the toner refill and replace the chip?

The original toner cartridge in a Kyocera ECOSYS P 2040 laser printer goes by the title TK-1160. To fill the refill toner into this toner cartridge a fill port is made, the residual toner is removed and the refill toner is filled in. To complete the refill we take off the old, empty chip on the TK-1160 and put a new, alternative chip on. See these different steps well explained in our refill instruction for the Kyocera TK-1160 laser toner cartridge.

The original Kyocera TK-1160 toner cartridge is basically a toner tank equipped with a toner chip and a toner port for releasing the toner powder towards the imaging parts of the printer. Thanks to the cartridge´s simple structure and the absence of wear parts, that have to be replaced, the toner refill is quite easy to do. The standard page yield of the TK-1160 toner cartridge is 7.200 pages.

Our first idea for refilling the empty cartridge was to go the original way of the toner powder - there is a round fill port on the TK-1160 cartridge´s housing. This port is closed by a plastic plug. But we realized that the plug and the housing are melted together. This makes it almost impossible to get the plug out of the port without damaging either the plug or the port. In each case it is very difficult to seal this fill port again securely after filling in the new toner. It is a really important priority to avoid producing a toner leaking, refilled Kyocera TK-1160 cartridge.

Another opportunity for refilling toner into the cartridge without any modification to the cartridge we thought could be the toner port at the bottom. The port is closed with a sliding lid that opens automatically when the TK-1160 cartridge is installed into the laser toner printer. Right behind the opening there is the toner transport roller. Its task is to move the toner from inside the cartridge to the toner port and at the same time it prevents us from refilling toner using that port as we cannot fit our funnel into this opening properly.

On the cartridge´s outsides there is also the toner chip. This chip identifies the cartridge as a TK-1160 cartridge towards the printer and creates toner level related messages.

Due to the restrictions mentioned before we decided to create the fill port in the upper side of the cartridge´s housing. The upper side is flat and also points upwards when the cartridge is installed inside the printer. This is reducing the risk of toner leaking from the fill port into the Kyocera laser printer. Suitable to the size of our funnel, which is used to fill refill toner into the cartridge, we have the melting tool available for creating the right sized fill port in the cartridge´s housing.

Take sufficient time and let the melting tool heating up. Then place the melting cap in the left, lower corner on the plastic housing. Press the melting tool on the cartridge TK-1160. The housing material is not very thick at this point and the melting the plastic quite quickly and slides into the cartridge. Pull the tool upwards and the inner part of the melted fill port will be inside the melting cap. In the cartridgeßs housing there is now a round opening for refilling toner. The advantage of melting the fill port is that it is free a shavings. Such plastic shavings can cause problems when beeing mixed with toner powder inside the Kyocera cartridge and coming to other parts as for example the transfer unit.

The next step in refilling the Kyocera Tk-1160 cartridge we recommend to do outside. We have a special vacuum cleaner suitable to clean out the residual toner from the empty cartridge. But most cases such a tool will be not beeing available. Empty the residual toner from the toner cartridge TK-1160 directly into a trashcan or a trashbag. The positioning of the melted fill port allows You to shake the residual toner to this corner and from there out of the cartridge. Please do not use a household vacuum cleaner to clean out the residual toner ! The filters in such a vacuum cleaner are not capeable of holding back the fine toner particles. When toner is sucked into the vacuum cleaner´s electric motor there is the danger that it might explode.

The toner funnel fits the fill port properly.

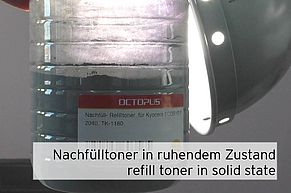

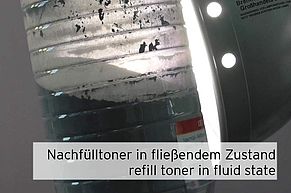

How to fill toner from a toner bottle into the toner cartridge? When looking on a toner bottle against a light source You can see that the toner is in a kind of solid state and rests on the bottle´s bottom. To fill the toner from the bottle we make use of a special characteristic of the toner powder. If You shake the toner in the bottle the flowing property of the toner changes significantly. When shaking the toner mixes with the air inside the bottle and this mix is behaving similar as a fluid. The toner-air-mix is flowing from side to side when tilting the bottle. In this fluid state the toner can be filled from the bottle, through the funnel and through the fill port on the Kyocera TK-1160 cartridge.

To coordinate toner bottle with funnel and the fill port on the toner cartridge we hold the cartridge in one and the bottle with funnel in the other hand. We slip the empty cartridge´s fill port over the funnel on the bottle to avoid spilling toner powder from the bottle. Make sure to press the funnel into the fill port properly during the whole refill procedure. Tilt the cartridge from side to side to distribute the toner inside the toner tank and knock the cartridge on the working area from time to time to shake up the toner in the bottle - funnel pressed into the fill port all the time.

To check that the complete amount of refill toner has been filled from the bottle into the Kyocera TK-1160 cartridge simpy hold the bottle against a light source again. As You can see in the picture there is no toner inside the bottle anymore. Now it is safe to separate the toner bottle from the cartridge again. Pay attention that the fill port on the cartridge is the highest point and just then pull the funnel from the fill port carefully. This way the toner can not leak out of the cartridge again. Please do not repeat our mistakes.

To close the fill port on the Kyocera TK-1160 cartridge we recommend to use fabric tape. This kind of tape is, up to certain amount, resistant towards heat - suffcient towards the temperatures inside the laser printer. The dimensions of the piece of tape we choose that the fill port and its surroundings can be covered and that there is some overhang to the sides. Press the tape flat on the upper side on the cartridge and wrap the overhang around the corners. On the edge we have made a cut on the tape to be able to lay the folds of tape above each other.

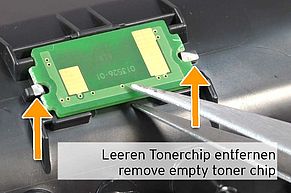

All refill toner has been filled into our Kyocera TK-1160 cartridge, the fill port is closed and now the cartridge is in the need of a new alternative toner chip. The original Kyocera ship is hold in its place inside the holder by two little plastic melting points. The tips of these points we have cut off and then the old Chip can be taken off. Keep the positioning of the chip in mind, the new alternative chip must be plaaced on the cartridge the same way. It helps to tape the old chip beside the holder in the alignment as the new chip needs to be put into the holder.

To fix the replacement chip in the holder on our Kyocera TK-1160 we use super glue. On the chip´s resting points in the holder we put four small glue dots. The used super glue used in our case has some kind of gel consistency, thank to that the glue dots stay on their place nicely. When setting the new chip in its position in the holder start with placing it on its lower resting points first and then tilting it on the upper resting points. By doing so it is easier to reach the correct position.

Make sure that there is no glue covering the chip´s contacts and electrical circiuts on the chip board. To limit the squeeze out on the chip try to use a few glue as possible.

Toner refill done, cartridge closed and replacement toner chip mounted - now the refilled Kyocera TK-1160 cartridge can be installed into the laser printer again. Our printer model is the Kyocera ECOSYS P 2040. The cartridge´s position after installation into the printer is that eh cloed fill port is pointing upwards - minimizing the risk of toner leaking into the printer - we just wanted to mention this onece more to advertise the position recommended fill port position. Thanks to the new toner chip the TK-1160 cartridge is recognized and has a full toner level. Shortly after recognition You are able to work and print again.

Soldering Iron, Hole making Tool

Soldering Iron, Hole making Tool

Funnel for Toner Powder, Toner Refills

Funnel for Toner Powder, Toner Refills

Adhesive Tape to close the Filler Hole, 2.75m

Adhesive Tape to close the Filler Hole, 2.75m

![[Translate to Englisch:] Lochschweißaufsatz aufgeheizt auf Kartuschengehäuse drücken](https://www.octopus-office.de/info/fileadmin/_processed_/f/2/csm_8-melting-fill-port-refill-_ed7f26ba8f.jpg)

![[Translate to Englisch:] Einfüllöffnung spanfrei hergestellt an Gehäuse TK-1160](https://www.octopus-office.de/info/fileadmin/_processed_/1/4/csm_9-tk1160-befuelloeffnung-oh_93f6b34691.jpg)

![[Translate to Englisch:] Klebepunkte auf seitlichen Auflagepunkten des TK-1160 Chips](https://www.octopus-office.de/info/fileadmin/_processed_/2/5/csm_22-befestigung-tonerchip_cf8269d6ec.jpg)

![[Translate to Englisch:] Neuer, alternativer Tonerchip auf TK1160](https://www.octopus-office.de/info/fileadmin/_processed_/7/6/csm_23-new-tonerchip-TK1160_4649c5c3ba.jpg)

![[Translate to Englisch:] Nachgefüllte TK-1160 Tonerkartusche im ECOSYS P 2040](https://www.octopus-office.de/info/fileadmin/_processed_/0/b/csm_24-refilled-Kyocera-TK1160_5eb9e0781d.jpg)

![[Translate to Englisch:] TK-1160 mit neuem Chip erfolgreich erkannt](https://www.octopus-office.de/info/fileadmin/_processed_/d/d/csm_25-TK-1160-erfolgreich-erkannt_3472fe1403.jpg)